1.5" Piston

For a very powerful pneumatic spudgun, a homemade piston valve or diaphragm valve is almost a necessity. I chose to make a piston valve. The valve is a chamber sealing valve, similar in nature to the supah valve. Here are my plans for the valve:

This is a piston valve I made after I broke my other piston valve. It was probably for the better that it broke, as it gave me a chance to redo all of my mistakes and incorporate some things I had learned. The valve can be constructed for about $20, $9 of which is for the ball valve. The chamber is at the front, opposite of the pilot/ball valve side. The Inside Diameter of the seat is 1.364", which should be comparable to dual sprinkler valves. The valve is able to exhaust through a 1/4" ball valve.

The front is a 1.5" FPT x spig adapter, which has the seat passing through it. The adapter was bored out to make room for the seat pipe to pass through. The seat is made from a piece of 1.25" sch40 which has been turned down to fit inside of the tee. The top of the tee is a 1.5" MPT x spig adapter. The tee is of course 1.5" sch40. At the back the tee has a piece of 1.5" pipe inserted. This acts as the guide pipe for the piston. The guide pipe has a 1.5" FPT x socket fitting attached to it, which is plugged with a 1.5" pressure rated plug. The plug has mounted in it: a 1/8" Schrader valve and a 1/4" pipe nipple, attached to a 1/4" ball valve. Now, for the most important part, the piston! I bought some 15/8" solid PVC rod from McMaster. It is surprisingly cheap, only $5 a foot. An o-ring groove was cut into the piston. This is important, because in this type of piston, the pilot must be absolutely airtight from the barrel. The piston was turned down on a lathe to go into 1.5" sch40 pipe. On the top of the piston there is a neoprene fender washer, found for only 23 cents at a local hardware store. The neoprene washer is held in place with a metal fender washer and 3 sheet metal screws. The piston has an equalization port (also what fills the chamber) drilled through it. The port is not extremely large, but it can only be so big to allow the piston to push back and equalize properly.

Pic of the piston valve

Final piston design, machined from solid PVC

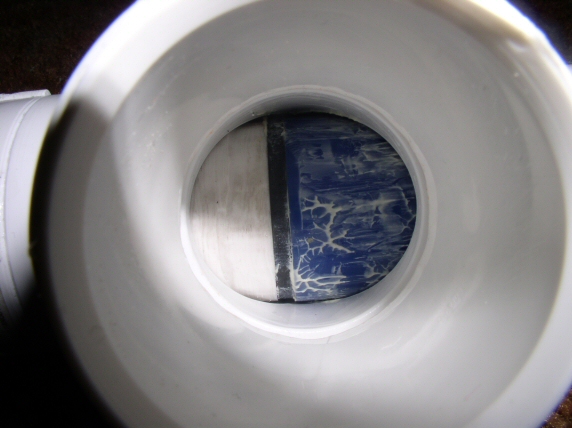

View of seat area and the piston.

Back view of the piston and inside of the 1.5" plug

This was a prototype wax piston.

Pic of the valve seated

Pic of the valve open

Animation of how the valve works

Not very elegant, but this is the bumper